Refrigeration units place significant strains on electric grids. In addition to their annual running costs, units often contain hazardous materials that require proper disposal and recycling as they are phased out of inventory.

Providing a foundation to build an eco-conscious facility starts with the installation and use of environmentally safe products. Refrigeration units are no exception. The government monitors and rewards organizations who meet or exceed standards, reinforcing the importance of having discussions on the sustainability and eco-friendliness of initiatives during all parts of the planning and implementation process.

As manufacturers continue to enhance and develop models, upgrading or installing eco-friendly refrigeration units makes both business and environmental sense.

Is the Price Worth It?

The common misconception is “green products” cost more. While this may hold some truth when looking at item price tags, the long-term environmental benefits often accompany rich financial gains. For a familiar example, think about LED lighting. Here is a product with a higher per unit cost than traditional bulbs but offers facilities less electrical fees and lessens the need for halogen and other hazardous materials to be removed and disposed of properly. Refrigeration units are similar, where the long-term benefits will outweigh the upfront cost.

New Regulations on the Horizon

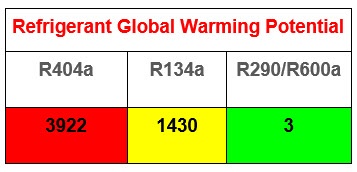

The Environmental Protection Agency has re-evaluated the impacts caused by refrigeration products and is about to officially set the bar higher. While most new regulations will be enforced closer to 2020, manufacturers are preparing their production facilities and product lines. The initiative revolves around phasing out traditional freon systems and replacing them with the greener hydrocarbon refrigerants like R290 and R600.

Hydrocarbon (HC) refrigerants are natural, non-toxic refrigerants that have no ozone depleting properties and low Global Warming Potential (GWP).

Products Already Changing in Response

Manufacturers have already made changes. For over 25 years American BioTech Supply (ABS) has been providing refrigeration equipment to major medical, university, biotech, pharmaceutical & government facilities. Even with such an established product line, ABS continues to push themselves to offer environmentally responsible solutions and has made the switch to Natural Hydrocarbon Refrigerants. Way ahead of the government deadlines, the company is converting the ABS product line to R290 and R600 refrigerants.

But ABS is not the only company making moves ahead of 2020. Migali has recently released an updated Genesis Series, focused on the use of these green hydrocarbon systems. Migali forecasts these newer systems will cut refrigeration energy costs by up to 40 percent, allowing for a greener Earth while saving some green in the client's annual budget. The company’s hydrocarbon models are easy to identify by the letters “HC” in the suffix of their model number.

Migali’s green initiatives are not solely reflected in their products, but also in their business culture. The company has vowed to plant a tree for every product they sell. It’s part of their long-term vision to plant enough trees to entirely off-set their lifetime carbon footprint.

Follett is another manufacturer focused on environmental sustainability and green initiatives. Follets Ice Manager™ diverter valve system is designed to save energy by allowing a single ice machine to fill two dispense points. Less machines mean lower operating costs, and small budget spends during design and planning stages.

But Follett doesn't stop there. All of their ice machines, ice and water dispensers, undercounter refrigerators and freezers use environmentally-friendly refrigerants – either R404a or R134a. The company also focuses on water use conservation, with the Horizon™ series and Maestro

How CME Can Help

CME Corp is not only your gateway to eco-friendly products and equipment. Choosing and ordering the right equipment can be time-consuming. Making an important decision on your new equipment can require more than a quote: CME makes sure you get everything you need to make an informed decision. We can offer budget-conscious alternatives as well as arrange demos and trials.

Along with helping you get the right equipment, CME has a complete array of logistics services to help you get your new equipment assembled and delivered to the room.

Check out two of our resources Streamlining the Healthcare Supply Chain and PVC Alternatives: Eco-Friendly Furnishings. For more information about any of our services or products, call us at 800-338-2372 and let us quote your next healthcare equipment project!

About CME: CME Corp is the nation’s premier source for healthcare equipment, turnkey logistics, and biomedical services, representing 2 million+ products from more than 2,000 manufacturers.

With two corporate offices and 35+ service centers, our mission is to help healthcare facilities nationwide reduce the cost of the equipment they purchase, make their equipment specification, delivery, installation, and maintenance processes more efficient, and help them seamlessly launch, renovate and expand on schedule.